Produktkategorier

Produkt Tags

CNC fræsning og drejning i rustfrit stål Pris

De vigtigste egenskaber af rustfrit stål

Bearbejdeligheden er meget dårligere end for medium kulstofstål. Tager bearbejdeligheden af almindeligt nr. 45 stål som 100%, den relative bearbejdelighed af austenitisk rustfrit stål 1Cr18Ni9Ti er 40%; Den relative drejningsbearbejdelighed af ferritisk rustfrit stål 1Cr28 er 48%; Martensitisk rustfrit stål 2Cr13 er 55%. Blandt dem, austenitisk og austenitisk + ferritisk rustfrit stål har den dårligste bearbejdelighed.

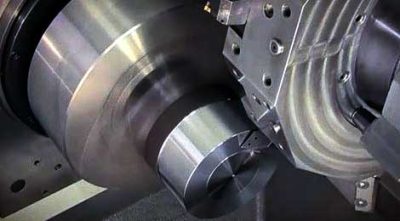

Cutting stainless steel is the process of processing stainless steel parts according to drawings with machining equipment such as lathes, fræsemaskiner, and planers.

De vigtigste egenskaber af rustfrit stål

Bearbejdeligheden er meget dårligere end for medium kulstofstål. Tager bearbejdeligheden af almindeligt nr. 45 stål som 100%, den relative bearbejdelighed af austenitisk rustfrit stål 1Cr18Ni9Ti er 40%; Den relative drejningsbearbejdelighed af ferritisk rustfrit stål 1Cr28 er 48%; Martensitisk rustfrit stål 2Cr13 er 55%. Blandt dem, austenitisk og austenitisk + ferritisk rustfrit stål har den dårligste bearbejdelighed.

The main features of stainless steel CNC machining

Severe hardening during CNC machining

Among stainless steels, the work hardening of austenitic and austenitic + ferritic stainless steels is the most prominent. For eksempel, the strength σb of austenitic stainless steel after hardening reaches 1470~1960 MPa, and with the increase of σb, the yield limit σs increases; The annealed austenitic stainless steel σs does not exceed 30% til 45% of σb, but it reaches 85% til 95% after work hardening. The depth of the work hardened layer can reach 1/3 or more of the cutting depth; The hardness of the work hardened layer is 1.4 til 2.2 times higher than the original. Because of the large plasticity of stainless steel, the character is distorted during plastic deformation, and the strengthening coefficient is large; And the austenite is not stable enough, part of the austenite will be transformed into martensite under the action of cutting stress; Ud over, under the action of cutting heat, the compound impurities are easy to decompose and present a dispersed distribution, which causes a hardened layer during cutting. The work hardening caused by the previous turning feed or the previous machining process seriously affects the smooth progress of the subsequent processes.

High cutting force

Stainless steel has large plastic deformation during cutting, especially austenitic stainless steel (its elongation is more than 1.5 times that of No. 45 stål), which increases the cutting force. På samme tid, the work hardening of stainless steel is serious, and the thermal strength is high, which further increases the cutting resistance. It is also difficult for stainless steel chips to curl and break. Derfor, the cutting force for processing stainless steel is large. For eksempel, the unit cutting force of turning 1Cr18Ni9Ti is 2450 MPa, which is 25% higher than that of 45 stål.

High cutting temperature

Plastic deformation and friction with the tool during cutting are both large, resulting in a lot of cutting heat;

Ud over, the thermal conductivity of stainless steel is about 1/2~1/4 of that of No. 45 stål.

A large amount of cutting heat is concentrated on the interface between the cutting area and the tool-stainless steel chip contact, and the heat dissipation condition is poor. Under the same conditions, the cutting temperature of 1Cr18Ni9Ti is about 200°C higher than that of No. 45 stål.

Stainless steel chips are not easy to break

The plasticity and toughness of stainless steel are great, and the chips are continuous during turning, which not only affects the smooth operation of the operation, but also scratches the processed surface. Under high temperature and high pressure, stainless steel has a strong affinity with other metals, and it is easy to cause adhesion and form built-up tumors, which not only aggravates tool wear, but also tears and deteriorates the processed surface. This feature of martensitic stainless steel with lower carbon content is more obvious.

Turning tools are prone to wear

Affinity force in the process of cutting stainless steel:

It will cause bonding and diffusion between the tool and the chips, so that the tool will produce bonding wear and diffusion wear, resulting in crescent craters on the rake face of the tool, and the cutting edge will also form tiny peeling and notches;

Ud over, the carbides in stainless steel (such as TiC) have high hardness. Direct contact with and friction with the tool during cutting, abrasion of the tool, and work hardening will all increase tool wear.

Stainless steel has a large linear expansion coefficient

The coefficient of linear expansion of stainless steel is about 1.5 times that of carbon steel. Under the action of cutting temperature, the workpiece is prone to thermal deformation, and the dimensional accuracy is difficult to control

Precautions for CNC machining stainless steel

Forholdsregler for drejning af rustfrit stål

Precautions for milling stainless steel parts

The price of CNC machining stainless steel

Kontakt os

Venter på din e-mail, vi vil svare dig inden for 12 timer med værdifuld information, du havde brug for.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe