Produktkategorier

Produkt Tags

10 materialer til prototyper til CNC-bearbejdning

Sammenlignet med 3D-print, den største fordel ved CNC-prototypen er rigdommen og anvendeligheden af materialer. Hovedformålet med prototypen er at verificere gennemførligheden af produktdesignet, så materialerne i prototypen er også meget specielle. Hver virksomheds produkter er forskellige, og prototypemodellerne, der skal laves, er også forskellige. Derfor, produktionsmaterialerne kan også være anderledes, men de vigtigste forarbejdningsmaterialer omfatter følgende:

Sammenlignet med 3D-print, den største fordel ved CNC-prototypen er rigdommen og anvendeligheden af materialer. Hovedformålet med prototypen er at verificere gennemførligheden af produktdesignet, så materialerne i prototypen er også meget specielle. Each company's products are different, og prototypemodellerne, der skal laves, er også forskellige. Derfor, produktionsmaterialerne kan også være anderledes, men de vigtigste forarbejdningsmaterialer omfatter følgende:

2. PC: Material with good strength, toughness and transparency, suitable for the production of Lens and fine structure parts. Ud over, glass fiber is added to improve the steel and heat resistance of the board, which can be used to make parts that need to maintain high rigidity in a high temperature environment. PC also has UL94-V0 fire rating;

3. PMMA: Namely acrylic, or plexiglass. It is a good transparent part, the material with the best transparency can be made with surface treatment such as dyeing, galvanisering, spraying, and screen printing. The welding strength is acceptable, but fragility is its weak point, and it is not suitable for use in vulnerable places such as hooks;

4. PP: Translucent material, good impact resistance, excellent flexibility, can be applied to products with strict impact resistance conditions. Såsom: automotive supplies, half-folding packaging boxes, etc.

5. PA66+GF30: PA66+GF30 is not a model, it is a general code for PA66 plastic materials with 30% glass fiber. High strength, special thermal stability, hydrolysis resistance, suitable for auto parts, mechanical parts, etc. It is used as a shield for mechanical parts that require high rigidity and dimensional stability. Red phosphorus flame retardant has long-term stability and excellent mechanical processing performance;

6. POM: It is called polymethine raw material in Chinese, also known as polyoxymethine raw material. It is often called Saigang in the prototype industry. The regular molecular structure and crystallinity make its physical and mechanical properties very excellent, and it is called metal plastic. In the prototype model, it is suitable for high-strength workpieces, such as gears, aksler, beslag, etc.;

7. Teflon: The chemical name is polytetrafluoroethylene (PTFE for short), which is generally called "non-stick coating" eller "easy to clean material". This material is resistant to acids, alkalis, and various organic solvents, and is almost insoluble in all solvents. På samme tid, PTFE has the characteristics of high temperature resistance, and its friction coefficient is very low, so it can be used for lubrication and become an ideal coating for easy cleaning of the inner layer of water pipes;

8. Aluminum alloy: Aluminum alloy is the most widely used non-ferrous metal structural material in prototype models, og har været meget brugt i luftfarten, rumfart, automotive, medicinsk, and ship prototype models. På nuværende tidspunkt, aluminum alloy is the most used alloy in prototypes. The advantages are easy processing and forming, good rigidity, and rich anode coloring;

9. Magnesium alloy: light weight and good strength, it is a favorite material for consumer 3C. The disadvantage is that magnesium is a flammable metal, and environmental control is very important during machining. The manufacturing process of magnesium alloy model is highly dangerous, and there are many machining processes after die-casting during production, which is a high-cost application material;

10. Messing: Brass is an alloy composed of copper and zinc. Brass composed of copper and zinc is called ordinary brass. If it is a variety of alloys composed of two or more elements, it is called special brass. Brass has strong wear resistance. Brass is often used in prototype models to replace materials that are difficult to engrave and mill, such as stainless steel. After polishing and electroplating, the surface effect and feel are very close to stainless steel.

CNC machined ABS prototype

CNC machining PC prototype

CNC machining PP rapid prototype

Aluminum alloy rapid prototyping

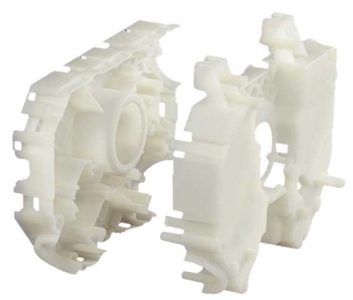

CNC machining POM rapid prototyping

Kontakt os

Venter på din e-mail, vi vil svare dig inden for 12 timer med værdifuld information, du havde brug for.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe