Indstil skæremængden af højhastigheds stålfræser til fræsning af rustfrit stål og valg af fræser

Først og fremmest, kølevæsken vil afkøle spånerne for hurtigt og smelte ind i klingen, hvilket resulterer i reduceret værktøjslevetid;

For høj tilførselshastighed vil forårsage materialeophobning, mens en for lav tilspændingshastighed vil forårsage friktion mellem værktøjet og emnet, og vil også forårsage overophedning.

Faktisk, for at undgå kanten af kniven, CNC-bearbejdning i rustfrit stål skærevarme er nødvendig. Til rustfri stålfræsere, den passende fræsehastighed skal vælges for at få spånerne til at have en lysebrun farve.

If the chips turn dark brown, it indicates that the cutting speed has reached the maximum limit. It is necessary to pay attention to the cutting speed when selecting the milling cutter when CNC machining stainless steel.

Parametre for højhastighedsfræsning af rustfrit ståldele

Cutting tools should be rigid, advanced, and have the highest possible overload capacity. It is best to mill stainless steel below 75% of the machine’s load calibration capacity.

Both the workpiece and the tool should be clamped firmly, and the extension of the tool should be as short as possible. Additional supports can be used if necessary. Whether it is a high-speed steel tool or a cemented carbide tool, it should be sharp at all times. It’s best to sharpen regularly, and don’t sharpen it when you have to.

Should use good performance lubricating fluid, such as chlorinated petroleum grease. This lubricant is particularly effective for powerful cutting where the feed rate is relatively slow.

For high-speed finishing cutting, it is recommended to use kerosene to dilute this lubricant. This mixed cutting fluid can keep the workpiece and tool at a lower temperature. Special attention should be paid to the cutting of Cr-Ni austenitic stainless steel. When cutting this stainless steel, you should be as careful as possible. It is possible to perform forced cutting to avoid pauses, so as not to cause work hardening and material slippage.

Egenskaberne ved fræsning af rustfrit stål er: The adhesion and melting of stainless steel are strong, og spånerne er nemme at klæbe til tænderne på fræseren, which deteriorates the cutting conditions; Ved opfræsning, skæretænderne glider først på den hærdede overflade, hvilket øger tendensen til arbejdshærdning; Ved fræsning, stød og vibrationer er store, hvilket gør fræserens tænder nemme at spåne og slide.

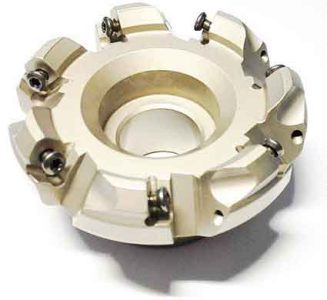

Milling tool for milling stainless steel parts

For milling stainless steel, except for end mills and some end mills, which can use cemented carbide as the material of the milling cutter teeth, the other types of milling cutters all use high-speed steel. I særdeleshed, tungsten-molybdenum series and high-vanadium high-speed steel have good effects, and the tool durability can be increased by 1 til 2 times compared with W18Cr4V. Hårdmetalkvaliteter egnet til fremstilling af rustfri stålfræsere er YG8, YW2, 813, 798, YS2T, YS30, YS25, etc.

Ved fræsning af rustfrit stål, the cutting edge must be sharp and able to withstand impact, og chipslommen skal være stor. Store spiralvinkelfræsere (cylindriske fræsere, endefræsere) Kan bruges, skruevinklen b øges fra 20° til 45° (n=5°), og værktøjets holdbarhed kan øges med mere end 2 gange. , Because at this time the working rake angle g0e of the milling cutter increases from 11° to over 27°, fræsningen er rask. Men værdien af b bør ikke være for stor, specielt til pindfræsere med b≤35°, for ikke at svække tænderne.

Use wave-edge end mills to process stainless steel pipes or thin-walled parts. The cutting is brisk, the vibration is small, the chips are fragile, og arbejdsemnet er ikke deformeret. Højhastighedsfræsning med endefræsere i hårdmetal og rustfrit stål med vendefræsere kan opnå gode resultater.

Milling 1Cr18Ni9Ti with a silver-white chip (SWC) end mill, dens geometriske parametre er gf=5°, gp=15°, af=15°, ap=5°, kr=55°, k′r=35°, g01= -30°, bg = 0,4 mm, re=6 mm. When Vc=50~90 m/min, Vf=630~750mm/min, and a’pb can reach 20=2~6mm, the milling power is reduced by 44% and the efficiency is greatly improved. The principle is to grind a negative chamfer on the main cutting edge, and artificially generate a built-up edge during milling, so that it can replace the cutting edge for cutting, and the rake angle of the built-up edge is ~~302. Due to the effect of the entering angle, the built-up edge is subjected to a thrust parallel to the cutting edge generated on a rake face and becomes a secondary chip flowing out, thereby taking away the cutting heat and reducing the cutting temperature.

Ved fræsning af rustfrit stål, down milling should be used as much as possible. The asymmetric down milling method can ensure that the cutting edge is smoothly cut away from the metal, and the contact area of the chip bonding blade is small. Under the action of high-speed centrifugal force, the chips are easily thrown away, so that when the cutter teeth re-cut into the workpiece, the chips impact the rake face and cause the phenomenon of blade spalling and chipping.

The spray cooling method has the most significant effect, hvilket kan øge fræserens holdbarhed med mere end det dobbelte; Hvis en general 10% emulsion bruges til afkøling, skærevæskens strømningshastighed skal sikres for at opnå tilstrækkelig afkøling. Når hårdmetalfræseren fræser rustfrit stål, take Vc=70~150 m/min and Vf=37.5~150 mm/min. På samme tid, appropriate adjustments should be made according to the alloy grades and workpiece materials.

share to:

| Type fræser | Milling cutter diameter D (mm) |

Rotating speed n (rpm) |

Feed rate f (mm/min) |

Bemærkninger |

| End mill | 3-4 5-6 8-10 12-14 16-18 20-25 32-36 40-50 |

1180-750 750-475 600-375 375-235 300-235 235-190 190-150 150-118 |

Manual Manual Manual 30-37.5 37.5-47.5 47.5-60 47.5-60 47.5-75 |

1) When the milling width and cutting depth are small, the feed amount is larger; Otherwise, take the small value 2) For milling cutters with three-sided edges, please refer to the same diameter disc milling cutter to select the cutting speed and feed 3) When the milling cutter is 2Cr13, the cutting amount can be adjusted according to the actual hardness of the material 4) When milling and cutting concentrated nitric acid resistant stainless steel, both n and f should be appropriately lowered. |

| Disc milling cutter | 75 110 150 200 |

235-150 150-75 90-60 75-37.5 |

23.5 or manual 23.5 or manual 23.5 or manual 23.5 or manual |

– |

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe