There are many reasons for the deformation of machined aluminum parts, which are related to the aluminum material, delens form, and the CNC machinery and equipment. Der er hovedsageligt følgende aspekter: blank internal stress, cutting force, deformation caused by cutting heat, and deformation caused by clamping force.

Process measures to reduce processing deformation

1. Reduce the internal stress of the blank. Natural or artificial aging and vibration treatment can partially eliminate the internal stress of the blank. Pre-processing is also an effective process method. For large blanks, the deformation after processing is also large due to the large margin. If pre-milling the excess part of the large blank. It can not only reduce the processing deformation in the subsequent process, but also can release a part of the internal stress after pre-processing.

2. Improve the cutting ability of the tool and the material of the tool. Geometric parameters have an important influence on cutting force and cutting heat. Det korrekte valg af værktøjer er afgørende for at reducere deformation af dele.

1) Reasonably choose the geometric parameters of the milling tool.

① The rake angle: Under betingelse af at bevare styrken af bladet, skråvinklen skal være passende større. På den ene side, den kan slibe skarpe skær, og på den anden side, det kan reducere skæredeformation, gør fjernelse af spåner glat, og derefter reducere skærekraften og skæretemperaturen. Brug aldrig værktøjer med negativ skråvinkel.

② Relief angle: Størrelsen af aflastningsvinklen har en direkte effekt på sliddet af flankeoverfladen og kvaliteten af den bearbejdede overflade. Skæretykkelse er en vigtig betingelse for at vælge aflastningsvinklen. Under grov fræsning, på grund af den store tilførselshastighed, stor skærebelastning og stor varmeudvikling, gode varmeafledningsforhold for værktøjet er påkrævet. Derfor, the clearance angle should be smaller. Ved færdig fræsning, the cutting edge is required to be sharp to reduce the friction between the flank face and the machined surface and reduce the elastic deformation. Derfor, the relief angle should be larger.

③ Helix angle: For at gøre fræsningen jævn og reducere fræsekraften, skruevinklen skal vælges så stor som muligt.

④ Entering angle: Appropriately reducing the entering angle can improve the heat dissipation conditions and reduce the average temperature of the processing area.

Method to prevent deformation of machined aluminum parts

2) Improve the milling tool structure.

① Reduce the number of milling cutter teeth and increase the chip space. Due to the large plasticity of aluminum materials, large cutting deformation during processing, and larger chip-capacity space is required, so the bottom radius of the chip-accepting flute should be larger and the number of milling cutter teeth should be smaller.

② Fine grinding of milling cutter teeth. The roughness value of the cutting edge of the tooth should be less than Ra=0.4um. Before using a new knife, you should lightly grind the front and back of the teeth with a fine oil stone to eliminate the residual burrs and slight serrations when sharpening the teeth. På denne måde, ikke kun kan skærevarmen reduceres, men også skæredeformationen er relativt lille.

③ Strictly control the wear standard of milling tools. Efter at værktøjet er slidt, overfladeruhedsværdien af emnet stiger, skæretemperaturen stiger, og deformationen af emnet øges. Derfor, ud over valget af værktøjsmaterialer med god slidstyrke, standarden for værktøjsslid bør ikke være større end 0,2 mm, otherwise it is easy to produce built-up edge. Ved skæring, emnets temperatur bør generelt ikke overstige 100°C for at forhindre deformation.

Filling method to prevent deformation of machined large aluminum parts

3. Improve the clamping method of the workpiece. For thin-walled aluminum workpieces with poor rigidity, the following clamping methods can be used to reduce deformation:

① For thin-walled aluminum bushing parts. If a three-jaw self-centering chuck or spring chuck is used to clamp from the radial direction, once it is released after processing, the workpiece will inevitably be deformed. På dette tidspunkt, the clamping method of the axial end face with better rigidity should be used. To locate the inner hole of the part, make a self-made threaded through mandrel, sleeve it into the inner hole of the part, press the end face with a cover plate and then tighten it with a nut. The clamping deformation can be avoided when the outer circle is processed, thereby obtaining satisfactory processing accuracy.

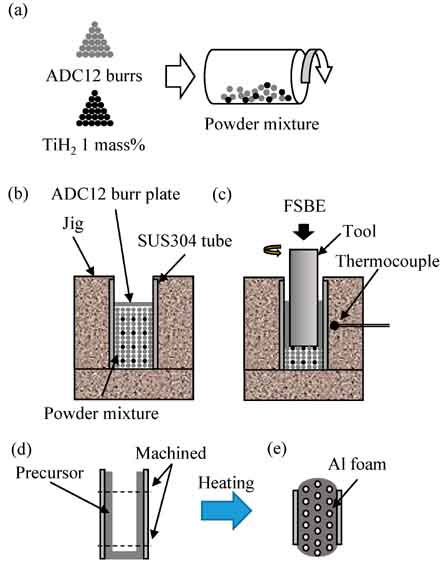

② When processing thin-walled and thin-plate aluminum workpieces, det er bedst at bruge vakuumsugekopper for at opnå jævnt fordelt klemkraft, and then process with a smaller cutting thickness (quantity), som godt kan forhindre deformation af emnet. Ud over, an internal filling method can also be used. For at øge processtivheden af tyndvæggede emner, medium kan fyldes inde i emnet for at reducere deformationen af emnet under fastspænding og skæring. For eksempel, hæld en urinstofsmelte indeholdende 3% til 6% kaliumnitrat ind i emnet. After processing, immerse the workpiece in water or alcohol to dissolve the filling and pour it out.

4. Arrange the procedures reasonably. Under højhastighedsskæring, due to the large machining allowance and continuous cutting, fræseprocessen giver ofte vibrationer, hvilket påvirker bearbejdningens nøjagtighed og overfladeruhed.

Derfor, the machining process of CNC high-speed cutting can generally be divided into: roughing – Semi-finishing – Clear corner processing – Finishing and other processes. Til dele med høje præcisionskrav, sometimes it is necessary to perform a second semi-finish machining and then finish machining. Efter grov bearbejdning, delene kan afkøles naturligt for at eliminere indre belastninger forårsaget af grov bearbejdning og reducere deformation. Den tilbageværende margin efter grovbearbejdning skal være større end mængden af deformation, generelt 1 til 2 mm. Under efterbehandling, delens efterbehandlingsoverflade skal opretholde en ensartet bearbejdningstillæg, generelt er 0,2-0,5 mm passende, så værktøjet er i en stabil tilstand under bearbejdningsprocessen. Det kan i høj grad reducere skærende deformation, opnå god overfladebehandlingskvalitet, og sikre produktets nøjagtighed.

In addition to the above-mentioned reasons, the operation method of aluminum parts is also very important in actual operation.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe