Nu om dage, bilforme har højere og højere krav til formoverfladekvalitet og skærehastighed. Den bedste fræsetilstand kan opnås, når det fem-aksede CNC-system bruges til at behandle et plan med tredimensionelle kurver. Indstillingsvinklen for værktøjsaksen kan ændres på enhver position i værktøjsmaskinens bearbejdningsområde for at behandle forskellige geometriske former.

3-axis machining center for processing deep cavity molds

3 axis machining center for deep cavity mold processing

The design of auto parts is mainly completed by CAD system, reverse engineering and various tests. The machining program for the complex surface of the mold comes from the CAM software, but how to ensure the accuracy of design and machining depends on CNC machining. The following discusses the relationship between the application of five-axis CNC system and mold quality in mold processing.

5-axis machining center is processing deep and steep cavities

Comparative application of 3-axis machining and 5-axis machining molds

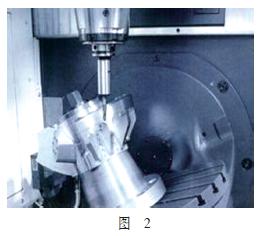

When the 3-axis machining center is processing deep cavity molds, it can only be achieved by lengthening the handle and cutting tools (se figur 1). Imidlertid, when the 5-axis machining center is processing deeper and steeper cavities, the additional rotation and swing of the workpiece or the spindle head can create the best process conditions for processing and appropriately shorten the tool length. It can avoid the collision of the tool and the tool holder with the cavity wall, reduce the jitter of the tool and the risk of tool damage during processing, thereby improving the surface quality of the mold, processing efficiency and tool life (se figur 2).

3-axis machining center processes the side wall of a mold

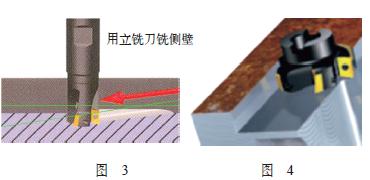

When a 3-axis machining center is used to process the side wall of a mold, the depth of the side wall determines the length of the selected tool, and the length of the tool must be greater than the depth of the side wall. As the tool length increases, the strength of the tool will decrease. If the tool length exceeds 3 gange diameteren, the tool will give way, and it is difficult to ensure the quality of the workpiece (se figur 3). The five-axis machining center is used to process the side wall of the mold workpiece, and the workpiece or the spindle can be swung to make the tool perpendicular to the side wall of the workpiece. Then use a plane milling cutter to mill the side wall, which can ensure the quality of the workpiece and extend the tool life (se figur 4).

Set ball cutter fine milling

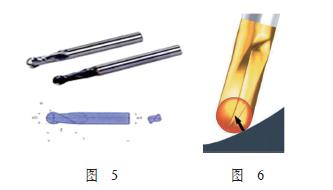

When using a 3-axis machining center to process a relatively flat surface, use a ball cutter to finish milling to get a better surface quality, so the tool path should be increased. But everyone knows that the linear velocity of the tool center of the ball-end knife is close to zero, so the tool is damaged greatly during the machining process, which shortens the tool life and deteriorates the surface quality (se figur 5). When using a five-axis machining center to process a relatively flat surface, in order to increase the relative linear velocity between the ball-end tool and the workpiece, som vist på figur 4, the tool and the workpiece are processed at a certain angle. The relative linear velocity between the tool and the workpiece increase ball, this would both improve the tool life, but also improve the surface quality of the workpiece (see FIG. 6).

Bearbejdning af det normale hul på det skrå plan med et fem-akset bearbejdningscenter

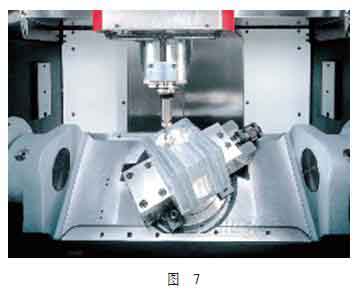

Ud over, when the 5-axis machining center is used to process the normal hole on the inclined surface. In the swing head type machine tool, the processing action is to place the spindle in the direction perpendicular to the inclined surface of the workpiece through the swing head and then position it to the position of the hole. Hole machining requires at least two linear axis interpolation motions to process the oblique hole, which greatly reduces the accuracy of the hole. When using a pendulum-type five-axis machining center for oblique face machining. The action is to place the inclined surface of the workpiece in the direction perpendicular to the spindle through the swing table, and only a linear axis movement of the spindle is required for hole processing. This greatly improves the accuracy of the hole (se figur 7).

Other advantages of the five-axis machining system

Nu om dage, bilforme har højere og højere krav til formoverfladekvalitet og skærehastighed. The best cutting state can be obtained when the five-axis CNC system is used to process a plane with three-dimensional curves. Indstillingsvinklen for værktøjsaksen kan ændres på enhver position i værktøjsmaskinens bearbejdningsområde for at behandle forskellige geometriske former. Irregular curved surfaces are processed by three-axis, and the direction of the cutting tool remains unchanged during the movement along the entire cutting path, so that the cutting state of the tool tip cannot always be perfect in all parts of the entire curved surface.

For deep grooves or curved surfaces that frequently change curvature, a five-axis CNC system is required for processing. The direction of the tool or the position of the worktable can be changed, and the cutting tool can always maintain the best cutting state. In the process of moving along the entire processing path, the tool direction can be optimized, and the tool moves in a straight line, so that all parts of the entire curved surface are perfect. If you want to mill a straight line with no direction change, the tool post can draw a straight line. If the direction changes at the same time, the tip of the tool draws a curve. If the tool tip can draw the required straight line when the direction is changed, this curve must be compensated, which is a crucial point in five-axis machining. In the case that the control system does not consider the tool length, the tool rotates around the center of the shaft. The tip of the knife will move out of its place and will not be fixed. If a five-axis control function is added to the control system, the control system only changes the direction of the tool, and the position of the tool tip remains unchanged. The necessary compensation movements on the X, Y, and Z axes have been automatically calculated to ensure the accuracy of processing.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe