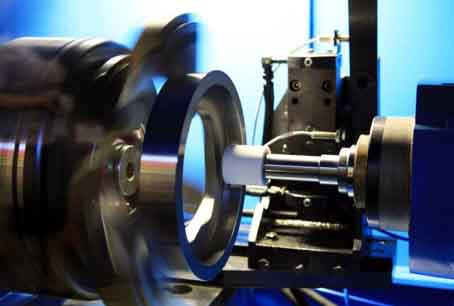

Mirror grinding technology of alloy parts

Cemented carbide is prepared by powder metallurgy with tool steel or alloy steel as the binder phase and refractory metal carbides (mainly WC, TiC) as the hard phase. Its structure is characterized by the fine hard phase grains dispersedly distributed in the steel base. The hard phase in the alloy mainly endows the material with high hardness and high wear resistance, and the binder phase in turn endows the material with the properties of steel. Derfor, the steel-bonded cemented carbide has the comprehensive properties of steel and cemented carbide, and it has been widely used in various fields.

The CNC machining of cemented carbide parts itself is very difficult, especially precision machining. This is because the hardness of the hard phase and the binder phase are quite different, the steel base is easy to be removed, and the hard points are not easy to be removed. And the crystal grains are easily peeled off from the surface of the alloy, thus forming pores with the same size as the hard phase crystal grains on the surface. På samme tid, the toughness of the steel base is great. Under certain grinding temperature, contact pressure and relative speed conditions, the grinding debris fills the pores between the abrasive grains, causing the grinding wheel to block the surface of the workpiece sharply and cause burns. Derfor, the traditional processing method is difficult to obtain low surface roughness, and the multi-stage grinding efficiency is low and the cost is high.

The use of on-line electrolytic continuous dressing (ELID) metal bond ultra-fine particle diamond grinding wheel to grind steel-bonded cemented carbide, the surface roughness can reach about 10 nm, and the efficiency is high. Using ELID mirror grinding technology to precisely process steel-bonded cemented carbide, it is easy to obtain a low-roughness mirror.

1. The basic principle of ELID grinding technology

Online electrolytic dressing mirror grinding is a new ultra-precision machining technology developed in Japan in the early 1990s. It uses cast iron or iron fiber bond diamond or CBN grinding wheel, and uses the anode dissolution phenomenon in the electrolysis process to perform online electrolytic sharpening and grinding of the grinding wheel. The electrolysis power supply adopts a DC pulse power supply, and the electrolyte adopts an aqueous solution of weak electrolyte. The cast iron grinding wheel is anode. During electrolysis, the iron element on the surface of the grinding wheel becomes Fe2O3 oxide film, which makes the diamond or CBN abrasive that cannot be electrolyzed protrude from the surface of the grinding wheel. The blunt abrasives fall off in time with the progress of electrolysis, so that the grinding wheel is always in a sharp state. På samme tid, the generated oxide film plays a role in inhibiting the continuation of the electrolysis process, so that the wear of the grinding wheel is not too fast. When the abrasive particles on the surface of the grinding wheel are worn, the oxide film is scraped and removed by the surface of the workpiece, the electrolysis process continues, and the surface of the grinding wheel continues to be trimmed. This is a cyclic process, which not only avoids the rapid wear of the grinding wheel, but also automatically maintains the grinding state of the grinding wheel surface, as shown in the figure below.

Schematic diagram of ELID grinding principle

2. ELID grinding technology applied to cemented carbide

The steel-bonded cemented carbide is subjected to mirror grinding, and the surface roughness of the workpiece is Ra=0.003 μm~0.011 μm. If a finer grinding wheel (above W1) is used, the Ra value will be significantly reduced and a better surface roughness will be obtained.

The surface roughness of the workpiece is not only closely related to the particle size and type of the grinding wheel abrasive used, but also closely related to the ratio of the grinding fluid. Grinding fluids with different compositions and contents have very different chemical properties, and the processed surface roughness is different.

Using HDMY-110 and HDMY-200 grinding fluids, we processed optical glass, sapphire, hardened steel, cementeret hårdmetal, cermet, PCBN, monocrystalline silicon wafer and other materials to achieve mirror effect. But for steel-bonded cemented carbide, a mirror surface that can reach 13 cannot be processed. Using special grinding fluid HDMY-201 and diamond, CBN mixed abrasive iron-based grinding wheel, under other conditions unchanged, a steel-bonded cemented carbide with a mirror surface (14) was ground. This is mainly because the composition and content of the grinding fluid have a great influence on the electrolysis speed, the film formation speed, the film thickness, the hardness of the film, and the surface structure and properties of the workpiece to be processed.

According to the different materials to be processed, reasonably adjust the composition and proportion of the grinding fluid, as well as the type and size of the iron-based grinding wheel abrasive, to obtain the best grinding state. So as to get a lower Ra value to meet the requirements of precision machining.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe