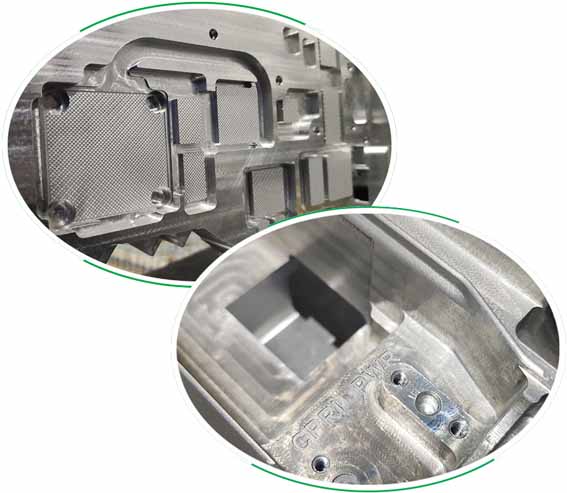

Projektet af aluminiumslegering køleplade prototype. Dens behandlingsmetode er CNC-behandling, og de anvendte overfladebehandlinger omfatter slibning, lasergravering og sandblæsning.

CNC-bearbejdning: cnc værktøjsapparat ovenfor, i henhold til den programmerede sti, bevægelsen i ovenstående materiale, det overskydende materiale fjernes del, hvorved prototypen af prototypemodellen.

Grinding: Because the surface of the radiator prototype processed by CNC has burrs and knife marks, it needs to be smoothed with sandpaper.

5G basestation køleplade hus

Lasergravering: Use a laser marking machine to mark the surface of the prototype to remove the surface material to form a permanent mark. For general metal marking, most of them use fiber laser marking machine.

Sandblæsning: Spray a layer of particles on the prototype surface to reduce the roughness of the prototype surface of the heat sink and make the prototype surface more exquisite.

Materiale: aluminiumslegering

Dataformat: STP/IGS/X.T/PRO

Kategori: CNC machining prototype model customization

Produktintroduktion: 5G base station equipment heat sink prototype, quickly grab market share, professional prototype processing;

Prototype details of the heat sink housing

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe