Reaming is to use a reaming drill to further process the drilled hole to enlarge the hole diameter and improve the accuracy and reduce the surface roughness value. The dimensional tolerance grades that can be achieved for reaming are IT11~IT10. The surface roughness value is Ra12.5~6.3μm. It belongs to the semi-finishing machining method of holes, which is often used as pre-processing before reaming, and can also be used as the final processing of holes with low precision.

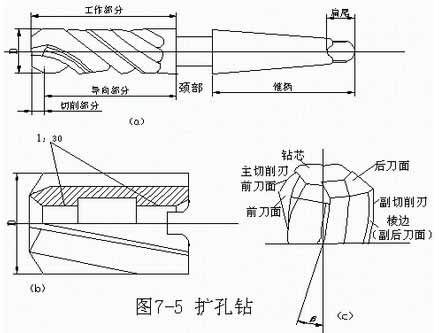

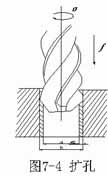

The reaming method is shown in Figure 7-4, and the reaming allowance (D-d) can be consulted in the table. The form of the reamer varies with the diameter. The diameter of Φ10~Φ32 is a taper shank reamer, as shown in Figure 7-5a. The diameter of Φ25~Φ80 is a sleeve type reaming drill, as shown in Figure 7-5b.

The structure of the reamer

Method of reaming

Compared with the twist drill, the structure of the reamer drill has the following characteristics:

1. Good rigidity. Due to the small cutting amount of the reaming hole and less chips, the chip pockets of the reaming drill are shallow and narrow, and the drill core diameter is larger, which increases the rigidity of the working part of the reaming drill.

2. Good orientation. The reaming drill has 3 na 4 teeth, the number of edges around the tool is increased, and the guiding effect is relatively enhanced.

3. The chip condition is better. The reamer has no chisel edge to participate in the cutting, and the cutting is brisk. Larger feed rate can be used, higher productivity;

Also, due to less chips, chip removal is smooth, and the machined surface is not easily scratched.

Proto, compared with drilling, reaming has higher machining accuracy, lower surface roughness value, and can correct the axis error of drilling to a certain extent. Navíc, the machine tool suitable for reaming is the same as for drilling.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe