Obrábění plastových výrobků nebo dílů lze rozdělit do dvou kategorií: single-edge tool machining and multi-blade tool machining. Single-edge tool processing includes turning, planing, and toothless saw processing. Multi-edge tool processing includes cutting, frézování, punching, klepnutím, and tooth saw processing.

(1) The formation process of plastic chips

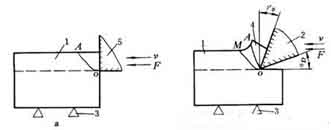

The forming process of plastic chips is extruded by cutting tools, jak je znázorněno na obrázku 1.

(2) Factors affecting cutting force

Cutting force is generated by deformation and friction, so all the factors that affect deformation and friction in the cutting process will affect the cutting force.

Chips from machined plastic parts

Postava 1. Formation of plastic chips

Cutting depth parameters of machined plastic parts

1― Workpiece; 2― Tool; 3― Fixture; 4― Chips; 5― Indenter

1. Types of Plastics

The higher the strength and hardness of the workpiece material, the greater the deformation resistance and the greater the cutting force. If the strength and hardness of the material are similar, the one with greater plasticity will have greater cutting force because of the greater friction between the chips and the rake face. Experiments have proved that the cutting force of CNC turning and milling of plastics is generally 1/6 na 1/7 of the cutting force of cutting steel.

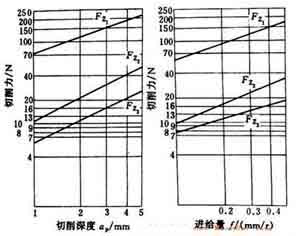

2. The influence of cutting amount

The increase of the back-cutting amount αP and the feed amount f will increase the cutting force, but the degree of influence of the two is different. The influence of the two on the main cutting force Fz is shown in Figure 2.

Cutting speed of machined plastic parts

Postava 2. The influence of cutting depth αP and feed rate f on the main cutting force Fz

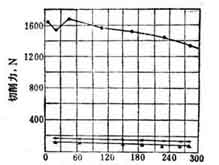

The influence of cutting speed v on the main cutting force Fz is shown in Figure 3. The amount of back cutting is αP=1.5mm, and the amount of feed f=0.2mm/r. It can be seen from the figure that the cutting speed v has little effect on the cutting force.

Postava 3, the influence of cutting speed v on the main cutting force Fz

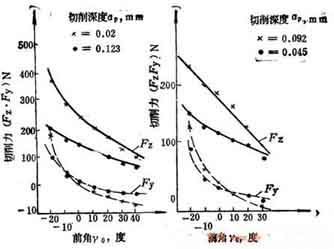

Cutting force of machined plastic parts

Postava 4, the influence of rake angle γ0 on cutting force

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe