Category: Aluminum alloy prototype / CNC machining prototype

Processing method: CNC processing

Material: aluminum alloy

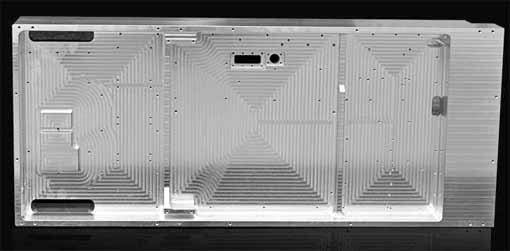

Product name: Machining laser aluminum housing cavity

Brand: Chinese KangDing prototype

Surface treatment: deburring

Processing cycle: 3 -7 seven working days

Testing standard: 3D drawings provided by the customer

CNC machining of aluminum alloy cavity prototype

High diffuse reflection laser cavity is mainly used for the production of pump cavity for solid and liquid laser devices. The structure adopts a tightly packed form, and uses a high-reflectivity diffuse reflection material as the reflector of the pump light source. Due to the design and structural characteristics of the highly diffuse reflection laser cavity, the energy of the pump light source is evenly distributed in the pump cavity, so that the laser material can absorb energy in a balanced manner. Thereby, the beam quality of the laser is greatly improved, the stability of the beam is improved, and the energy conversion efficiency is higher. In the choice of diffuse reflection materials for the highly diffuse reflection laser cavity, diffuse reflection materials with a reflectivity of nearly 100% are used, which have the characteristics of water repellency and long life, and slight pollution can be restored by cleaning. Compared with laser cavities of other structural forms, the highly diffuse reflection laser cavity also has the characteristics of relatively simple structure, low cost, convenient operation, maintenance and replacement.

Due to the extremely excellent performance of the highly diffuse reflection laser cavity, it has become an irreplaceable product for certain laser applications. It has been widely used in laser application fields such as scientific research, military, medical, industry, etc.

CNC milling laser cavity of aluminum alloy

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe