The use of short cutting tools is the main feature of five-axis machining. Short tools will significantly reduce tool deviation, thereby obtaining a good surface quality, avoiding rework, reducing the amount of welding rod used, and shortening the processing time of EDM. When considering five-axis machining, the goals of using five-axis machining molds must be considered:

Use the shortest cutting tool possible to complete the processing of the entire workpiece. It also includes reducing programming, clamping and processing time but can get a more perfect surface quality.

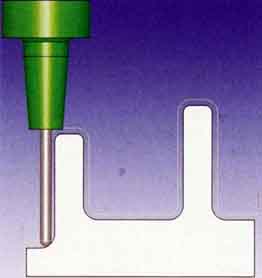

As long as the workpiece cavity is not very deep (relative to the tool diameter), a three-axis tool path (2, 3, 5) is sufficient. If the workpiece cavity is very deep and has very narrow parts, it is not enough to use a pure three-axis tool path to complete the entire finishing. في هذه الحالة, poor surface quality and long processing time ensue. شكل 1 is the case of a three-axis tool path. Here, the shortest tool must be very long in order to be able to machine all areas of the workpiece in the vertical direction.

3-axis machining path of short tool

شكل 1, Three-axis machining path

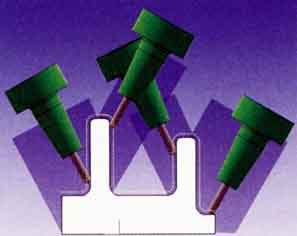

When using a shorter tool, the spindle should be tilted to ensure that the special area of the workpiece can be processed. 3+2 axis machining is usually considered as setting a constant angle to the spindle. Complex workpieces may require many oblique views to cover the entire workpiece, but this will cause tool paths to overlap and increase machining time.

فضلاً عن ذلك, all the oblique views are difficult to accurately combine, so the workload of manual polishing will increase, وفي نفس الوقت, it will greatly increase the movement in and out, which often leads to surface quality problems and more tool movement.

شكل 2, 3+2 axis tool pathFinally, programming in this way will interfere with each other and is time-consuming, and the sum of all views often cannot cover the entire geometry. شكل 2 demonstrates four workpiece views, but there is still an area in the center of the workpiece that cannot be covered. This area still needs an additional oblique view.

3+2 axis short tool machining path

شكل 3, 5-axis tool path

5-axis short tool machining path

من أجل التغلب على عيوب 3+2 تجهيز المحور, قد تكون المعالجة المتزامنة ذات خمسة محاور خيارًا أفضل, ناهيك عن أن بعض الأدوات الآلية ذات المحاور الخمسة لديها أيضًا بعض الوظائف المصممة خصيصًا لصناعة القوالب. يمكن لآلات الربط ذات خمسة محاور تنسيق ثلاثة محاور خطية ومحورين دوارين لجعلها تتحرك في نفس الوقت, الذي يحل جميع مشاكل 3 محاور و 3+2 تجهيز المحور. يمكن أن تكون الأداة قصيرة جدًا, لا يوجد تداخل في وجهات النظر, احتمال فقدان منطقة المعالجة أقل, ويمكن إجراء المعالجة بشكل مستمر دون استيراد وتصدير إضافي (أنظر للشكل 3).

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe