CNC machining thin-walled cavity technology

تتشوه أجزاء الألومنيوم وأجزاء تجويف الألومنيوم أثناء التصنيع باستخدام الحاسب الآلي. بالإضافة إلى الأسباب المذكورة في القسم السابق, في التشغيل الفعلي, طريقة التشغيل مهمة جدًا أيضًا.

1. For the cavity parts with large CNC machining allowance, من أجل الحصول على ظروف أفضل لتبديد الحرارة أثناء عملية التصنيع وتجنب تركيز الحرارة, يجب استخدام الآلات المتماثلة أثناء التصنيع. If there is a 900mm thick sheet that needs to be processed to 800mm, if one side is milled and the other side is milled immediately, and the final size is processed at a time, the flatness will reach 50mm; If using repeated feed symmetrical processing, each side is processed twice to the final size, and the flatness can be guaranteed to reach 0.3mm.

2. If there are multiple cavities on the aluminum sheet parts, it is not advisable to use a cavity-by-cavity sequential processing method during processing, as this is likely to cause uneven stress and deformation of the parts. Multi-layer processing is adopted, and each layer is processed to all cavities at the same time as much as possible, and then the next layer is processed to make the parts evenly stressed and reduce deformation.

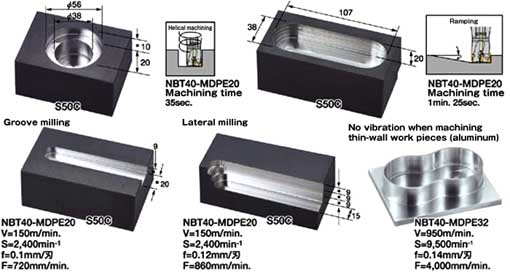

طحن قطع عمل الألمنيوم ذات الجدران الرقيقة

3. Reduce cutting force and cutting heat by changing the cutting amount. Among the three elements of cutting volume, cutting thickness has a great influence on cutting force. If the machining allowance is too large, the cutting force of one pass is too large, which will not only deform the parts, but also affect the rigidity of the machine tool spindle and reduce the durability of the tool. If the cutting thickness is reduced, the production efficiency will be greatly reduced. لكن, high-speed milling in CNC machining can overcome this problem. While reducing the cutting thickness, as long as the feed is increased correspondingly and the speed of the machine tool is increased, the cutting force can be reduced while ensuring the processing efficiency.

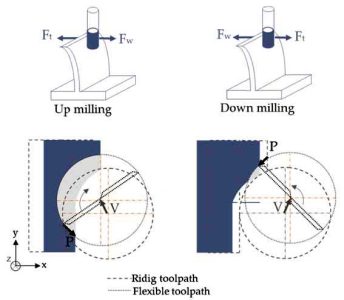

4. The order of the knife should also be paid attention to. Rough machining emphasizes the improvement of machining efficiency and the pursuit of removal rate per unit time. عمومًا, upside milling can be used. إنه, the excess material on the surface of the blank is removed at the fastest speed and the shortest time, and the geometric contour required for finishing is basically formed. The emphasis of finishing is high precision and high quality, and down milling should be used. Because the cutting thickness of the cutter teeth gradually decreases from the maximum to zero during down milling, the degree of work hardening is greatly reduced, and at the same time the degree of deformation of the parts is reduced.

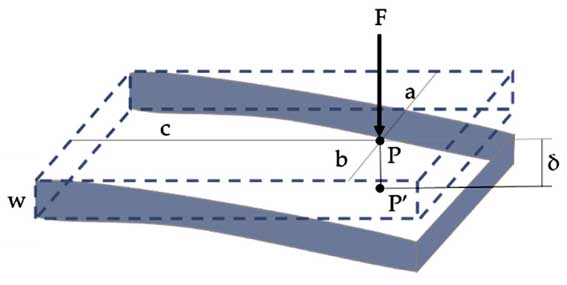

Cutting sequence of thin-walled aluminum cavity

5. The thin-walled aluminum cavity workpiece is deformed due to clamping during machining, and it is unavoidable even during finishing. In order to minimize the deformation of the workpiece, the clamping and pressing parts can be loosened just before the finishing process reaches the final size, so that the workpiece can be restored to its original state freely. Then slightly clamp and compress, as long as the workpiece can be clamped (completely by hand), so that the ideal processing effect can be obtained. In short, the point of action of the clamping force is best on the supporting surface, and the clamping force of the fixture should act in the direction of good rigidity of the workpiece. Under the premise of ensuring that the workpiece is not loose, the smaller the clamping force, the better.

6. When machining aluminum parts with a cavity, try not to insert the milling cutter directly into the part like a drill. نتيجة ل, the chip holding space of the milling cutter is not enough, and the chip removal is not smooth, resulting in unfavorable phenomena such as parts overheating, expansion, tool collapse and tool breakage. أولاً, drill the hole with a drill of the same size as the milling cutter or one size larger, and then mill with the milling cutter. بدلاً عن ذلك, the CAM software can be used to produce the spiral cutting program.

The main factor that affects the processing accuracy and surface quality of aluminum parts is that deformation is prone to occur during the processing of such parts, which requires operators to have certain operating experience and skills.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe