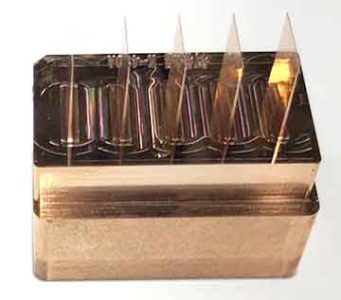

التصنيع باستخدام الحاسب الآلي من القطب النحاس

The copper electrode of the EDM machine, Also known as CNC machining of copper electrode mirror. It is an indispensable part in the processing of EDM machine.

أثناء تصنيع EDM, يتم توصيل القطب النحاسي وقطعة العمل على التوالي بقطبي مصدر طاقة النبض. يولد جهد النبض المطبق على القطب النحاسي وقطعة الشغل تفريغ شرارة. درجة الحرارة اللحظية للتفريغ يمكن أن تصل إلى 10,000 درجة مئوية, ودرجة الحرارة المرتفعة تجعل سطح قطعة العمل يتبخر أو يذوب جزئيًا.

القطب النحاسي لآلة EDM

Immediately after the next pulse voltage, a spark discharge is generated between the copper electrode and the workpiece, and the above process is repeated.

Through countless repetitive pulse discharges, a shape corresponding to the shape of the electrode is finally processed. لذلك, as long as the shape of the copper electrode is changed, various complicated profiles can be processed.

In EDM machining, the role of the copper electrode is to transmit processing pulses and to remove the workpiece with the minimum loss of the copper electrode itself. Commonly used electrode materials are copper, graphite, copper-tungsten alloy, silver-tungsten alloy, فُولاَذ, نحاس, cast iron, إلخ.

Mirror copper electrode

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe