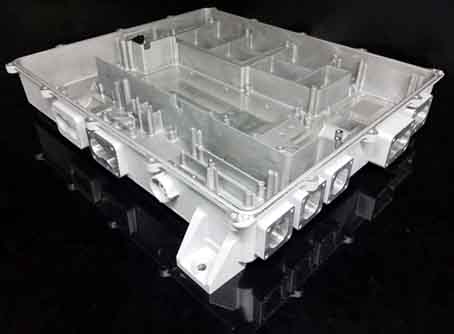

CNC machining aluminum battery box of new energy vehicles

CNC milling and processing of new energy vehicle power battery box manufacturers, partners in many companies at home and abroad, involving military, automotive, high-end medical, robotics and other industries. Our customized new energy vehicle power battery box adopts high-precision cnc turning and milling center customization, and the customization tolerance is very high. The waterway adopts friction stir welding technology, and the fully sealed waterway design can bear a pressure of 5kg. Whether it is air tightness or parallelism, the flatness is strictly controlled to ensure the safety of the power battery box of the new energy vehicle, and the water resistance is guaranteed.

New energy vehicle power battery box case show

With the rapid development of the electric vehicle industry, the safety of new energy power batteries, which are the core components of vehicles, is gradually showing up, and directly affects the safety and stability of the entire vehicle. The development of the power battery box for new energy vehicles is a relatively complicated process, and many factors need to be considered. At the same time, we must actively introduce and learn from the experience and technology of advanced countries, and continue to improve and verify the design of the new energy vehicle power battery box.

Therefore, the strength, rigidity, heat dissipation, and waterproof of the power battery box of the new energy vehicle require high design requirements. As a small pure electric vehicle that is the key development in China, the importance of its new energy vehicle power battery box cannot be ignored. In the actual design, not only the space limitation must be considered, but also its own safety and the impact on the performance of the whole vehicle must be fully considered.

Insulation of battery box

Generally speaking, the output voltage of the power battery pack of a pure electric vehicle can reach more than 200V. In addition to ensuring that the battery box contains the battery, the battery box should also be able to directly isolate the operator or passenger from it. Prevent accidental electric shock and leakage.

Water resistance of the battery box

In addition to insulation, the battery box must also be waterproof and kept in a sealed state to prevent short circuits caused by water ingress. In addition, the protection level of the battery box must reach IP67.

1. Control the distance between the two stages of the battery and the battery box. Generally, the minimum requirement is about 10mm to prevent breakdown discharge.

2. Make sure that the electrophoresis of the entire battery box is sprayed, especially the interior must be coated with insulating paint, or some insulating plates can be installed appropriately.

3. Be sure to apply sealant to the welds that affect whether the battery box can be sealed. At the same time, a sealed material should be installed at the junction of the upper cover of the battery box and the box. And the fixed place of the connector must adopt practical sealing measures

Battery box and safety

When a vehicle collides, the battery box should meet the following requirements:

1. If the power battery or battery pack is placed in the external environment of the passenger compartment, the corresponding power battery and other components cannot penetrate into the passenger compartment;

2. If the power battery box is installed inside the passenger compartment, any movement of the battery box must be based on ensuring the safety of passengers. Under normal circumstances, it is necessary to ensure that people and electricity are separated.

3. In the event of a collision, be sure to avoid the battery modules from being scattered in the battery box due to the collision. Special attention must be paid to completely avoid the situation where the battery box is thrown out from the top and bottom of the car;

4. Once a collision occurs, the first thing to do is to ensure that the overcurrent disconnect device of the battery pack is disconnected, and at the same time, to prevent the power battery pack from short-circuiting;

5. In the event of a collision, the rigidity of the battery box must be able to ensure that the deformation of the battery module is within the range that it can bear.

Carbon fiber composite material has a higher specific strength and specific modulus, and its specific strength is 5 times that of steel. The density of the composite of carbon fiber and epoxy resin is 1.4kg/m3. At the same time, carbon fiber composite materials also have excellent corrosion resistance, insulation and flame retardancy. The application of it in the battery box of electric vehicles can not only meet the design requirements, but also has a significant weight reduction effect compared with the traditional metal battery box in terms of light weight.

PREVIOUS:NONE

NEXT:Design the prototype of CNC machining car lamp rp part

NEXT:Design the prototype of CNC machining car lamp rp part