Product Categories

Product Tags

Finishing of aluminum alloy shell

Aluminum alloy shells are various shells made of aluminum alloy, generally including aluminum profile shells, aluminum die-casting shells, and machined shells.

Aluminum alloy shells are various shells made of aluminum alloy, generally including aluminum profile shells, aluminum die-casting shells, and machined shells.

Aluminum alloy shell is a variety of shells made of aluminum alloy. Because of its convenient processing, high flexibility and high grade, it can effectively increase the added value of products and can be widely used in the electronics industry. Generally include aluminum profile shell and aluminum die-cast shell, CNC machined shell.

Aluminum profile shell

An aluminum profile shell is a shell processed on an aluminum profile obtained by aluminum stretching. High flexibility, depth can be arbitrarily cut, generally there is a circuit board card slot inside. As long as the circuit board is directly inserted, there is no need to fix it. The convenience is unmatched by other types of housings. However, the aluminum profile shell generally has poor water resistance and is not suitable for use in the field and harsh environments. This kind of aluminum profile shell has a wide range of application prospects.

Aluminum die-cast housing

The aluminum die-casting shell adopts one-time die-casting molding technology, which has the characteristics of waterproof and explosion-proof, suitable for field use. But the price is higher and the flexibility is low. The size change of the aluminum shell can only be done by modifying the mold.

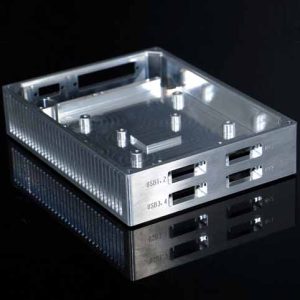

CNC machined communication aluminum chassis

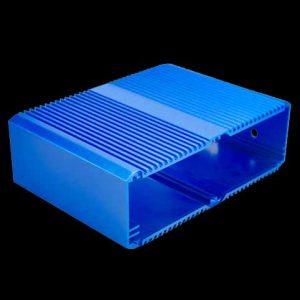

Profile of heat-dissipating aluminum machine housing

Communication equipment chassis of die-cast aluminum

Contact Us

Waiting for your email, we will reply you within 12 hours with valuable information you needed.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe