Geometric Motion Relations of Ball-end Milling Cutter Five-axis Milling

Milling can obtain a good curved approximate surface. When using a ball-end tool for three-axis milling, the linear feed motion in the x, y, and z directions can ensure that the tool cuts to any coordinate point on the workpiece, but the direction of the tool axis cannot be changed. The actual cutting speed of the point on the tool axis is zero, and the chip space in the center of the tool is also very small. If these points are involved in cutting, the unfavorable cutting conditions will cause the quality of the machined surface to decrease, the blade wear will increase, and the machining time will be prolonged. So that high-grade tool materials are not fully utilized.

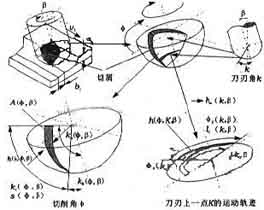

Compared with five-axis and three-axis milling, five-axis milling has a series of advantages. At this time, through the movement of the two rotating shafts, the direction of the tool axis can be adjusted at any time, so that the angle between the milling cutter axis and the workpiece surface and the actual cutting speed remain unchanged. The tool path path can be set more flexibly to meet the requirements of the given peak and valley depth of the workpiece surface. When a ball-end tool is used for machining, no matter what orientation the tool is relative to the workpiece, the chips are always separated on the hemispherical surface. Therefore, chips with the same geometry and size are always cut every time. What has changed is the motion trajectory of the blade when the chips are separated, as well as the contact conditions of the blade and the cutting geometric motion conditions determined thereby. In other words, the cutting process and geometric motion parameters can be affected by purposefully changing and determining the position of the tool, and the two can be optimized from the aspects of tool wear, surface quality and processing stability.

Of course, CNC programming for five-axis simultaneous milling is more complicated, and requires higher computing power and speed for the computer numerical control (CNC) system. While the linear feed axis of the machine tool is required to make a large compensation movement, it is also required to avoid interference and collision. Therefore, in mold manufacturing, only the advantages of five-axis milling can be used to process workpieces within a certain range.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe