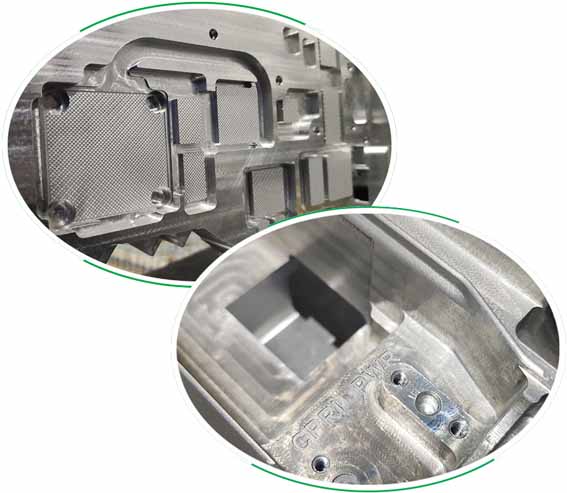

The project of aluminum alloy heat sink prototype. Its processing method is CNC processing, and the surface treatments used include sanding, laser engraving and sandblasting.

CNC machining: cnc tool apparatus above, according to the programmed path, the motion in the above material, the excess material is removed portion, whereby the prototype of the prototype model.

Grinding: Because the surface of the radiator prototype processed by CNC has burrs and knife marks, it needs to be smoothed with sandpaper.

5G base station heat sink housing

Laser engraving: Use a laser marking machine to mark the surface of the prototype to remove the surface material to form a permanent mark. For general metal marking, most of them use fiber laser marking machine.

Sandblasting: Spray a layer of particles on the prototype surface to reduce the roughness of the prototype surface of the heat sink and make the prototype surface more exquisite.

Material: aluminum alloy

Data format: STP/IGS/X.T/PRO

Category: CNC machining prototype model customization

Product introduction: 5G base station equipment heat sink prototype, quickly grab market share, professional prototype processing;

Prototype details of the heat sink housing

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe