For some low-volume or single-piece rapid prototyping manufacturing, turning and milling processing equipment is also very versatile. Because of its ability to control at least one rotary axis, its application range has been expanded, and it can even replace the work of a multi-coordinate linkage CNC machining center.

The following is the application of turning and milling processing equipment in CNC machining of impeller blades. As a typical part type of five-axis machining, blade machining has huge market demand. In fact, most of these parts can be completed on a turning and milling machining center. For some turning and milling equipment with B-axis linkage, the types of parts that can be processed will be more extensive. This kind of equipment not only has the turning function, but also can complete the milling work of 3-axis to 5-axis linkage. With the development of machine tool hardware, the rigidity of the machine tool has been significantly improved, and rough and finish machining can be completed at one time. And from a technological point of view, the turning-milling compound equipment has the advantages of simple clamping and positioning of parts, various rough machining methods, and convenient chip removal. At the same time, the price of turning and milling equipment is getting closer and closer to the same grade of multi-axis milling machining centers. Therefore, it is gradually becoming a reality to complete the processing of impeller blades on the turning and milling compound equipment.

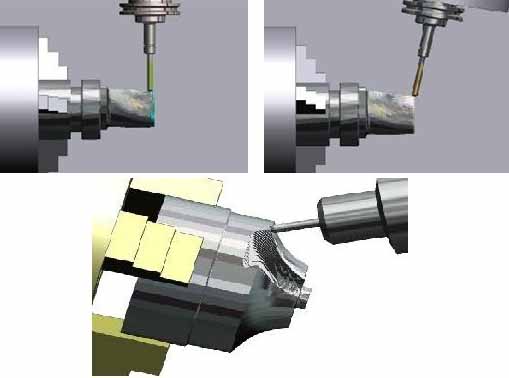

For ordinary C&Y turning and milling equipment, the blade can be processed by C-axis linkage. This type of control system is actually a three-axis control system. Through XZC three-axis linkage to complete the machining of the profile, there is no need to make more investment on the machine tool. Just select a CAM software that can provide this function. as the picture shows:

Rapid prototyping machining of turning and milling

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe