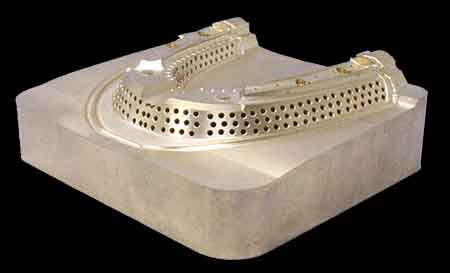

5-axis machining silicone mold

Overview of silicone compound mold

Silicone molds are suitable for trial production of prototypes in small batches (20-30 pieces) in the development stage of new products. Silicone molds have good toughness and can produce parts with complex structures, fine patterns, no draft angles, and even reverse draft angles. The production cycle is short and the product quality is high.

Silicone rubber molds generally use silicone rubber and reactive polyurethane materials, which is a relatively popular rapid mold manufacturing process.

What is silicone compound mold?

Remoulding refers to using the original original shape or template to make a silicone mold in a vacuum state, and use PU material for pouring in a vacuum state, thereby cloning the same copy of the original template.

Requirements for the laminating process of silica gel:

1. Prototype: Before making the silicone mold, you need to make a prototype. Prototyping can be used more common ABS material, CNC machining can be.

2. After the prototype of the silicone mold is ready, start making the silicone mold. After eight hours of drying, the silicone mold was cut open and the prototype was taken out. The silicone mold is now ready.

3. Injection type: Pour the liquid gum material into the silicone mold and dry it. The service life of the silicone mold is about 20 times.

Advantages and disadvantages of silicone laminating tools:

The advantage is that the time is fast, the cost is less, and the chance of machining failure is small. More than 20 pieces of the same product can be made with one silicone mold. Greatly reduce product development costs, cycles and risks.

The disadvantage is that the mold is not resistant to acid and alkali, not resistant to aging, and has a short life. Marks, streaks, and unevenness are easy to appear on the surface of the mold, and the product accuracy is not high.

Key points of the process of silicone coating tool:

1. The amount of curing agent added should depend on the temperature, and it will decrease when the temperature is higher. Excessive use of curing agent will make the mold hard and brittle;

If the curing agent is used too little, the operating time will be prolonged.

2. In order to prevent changes in the physical properties of the mold silicone, it is recommended not to add silicone oil.

3. In order to achieve the best use of your mold, please store the mold for at least 24 hours before use.

4. The hard mold can also be made of resin.

Application range of silicone compound mold:

Mainly used in the development of new product shells, smart product shells, car modification, medical shells, toys and gifts industry, craft gift industry, furniture decoration industry, character reproduction, Product replication and mold making in various industries such as building decoration and decoration industry, simulation of animal and plant sculptures, Buddha carving crafts, etc.