Intelligent CNC machine tools realize automatic turning and machining of parts

Intelligent CNC machine tool manipulator realizes automatic turning and processing of parts. Through the application of intelligent CNC machine tools to establish automated turning parts. It can meet the mass automatic processing of both sides of the motor shaft.

Project effect after applying CNC machine tool manipulator

1. After processing with intelligent CNC machine tools, it can save 5 personnel and reduce the labor intensity of workers. The introduction of advanced equipment greatly enhances the company's image.

2. To improve production efficiency and control production rhythm. In addition to the fixed production and processing cycle cannot be improved, automatic loading and unloading replaces manual operations, so that the cycle can be well controlled, and the impact on the production cycle due to human factors is avoided. Greatly improve production efficiency and realize automated mass processing.

3. The product quality is guaranteed. The intelligent CNC machine tool automatic production line, from loading, clamping, and unloading are completed by robots, reducing intermediate links and greatly improving the quality of parts. Especially the surface of the workpiece is more beautiful, and the stability of the quality is guaranteed.

Intelligent CNC machine tools realize automatic turning and machining of parts

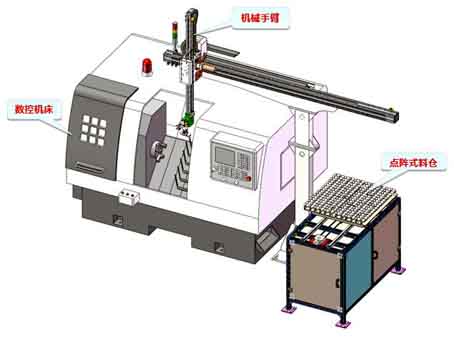

1. Composition of automated turning processing unit: Two CNC lathes can be served by one CNC lathe robot.

2. Layout of parts for automated turning: According to the requirements of the plant site, the CNC lathe adopts a right-angle structure. The intelligent numerical control machine tool is installed in the middle of the fence formed by the numerical control lathe, which is beneficial to increase the rate and save space and space.

3. Selection of robot: The diameter of the workpiece is 60-150mm, and the weight does not exceed 10kg. Mainly to complete two turning operations of parts. For multiple turning of the workpiece, it is necessary to design a relatively complex gripper.

4. The configuration of the feeding system of the machine tool: The feeding adopts double-station tray feeding. When the A station processing is completed, the robot automatically switches to the B station for reclaiming processing. Workers only need to change the pallet, and one filling can satisfy 8 hours of processing. Two CNC machine tools adopt the form of turning tables for reversing.

5. Design and manufacture of the gripper of the machine tool: According to the customer's workpiece shape and weight, we can independently design a multi-functional type for customers, which can take into account 6 kinds of different sizes of workpieces. It has the characteristics of simple model change, convenient maintenance and low cost.

6. Safety protection of machine tools: No personnel are allowed to enter the system working area. Therefore, the system is isolated by a safety fence and equipped with a safety door system. When the door is opened abnormally, the CNC lathe robot will emergency stop and alarm. If someone is working in the moving area, the robot is not allowed to start cycling.